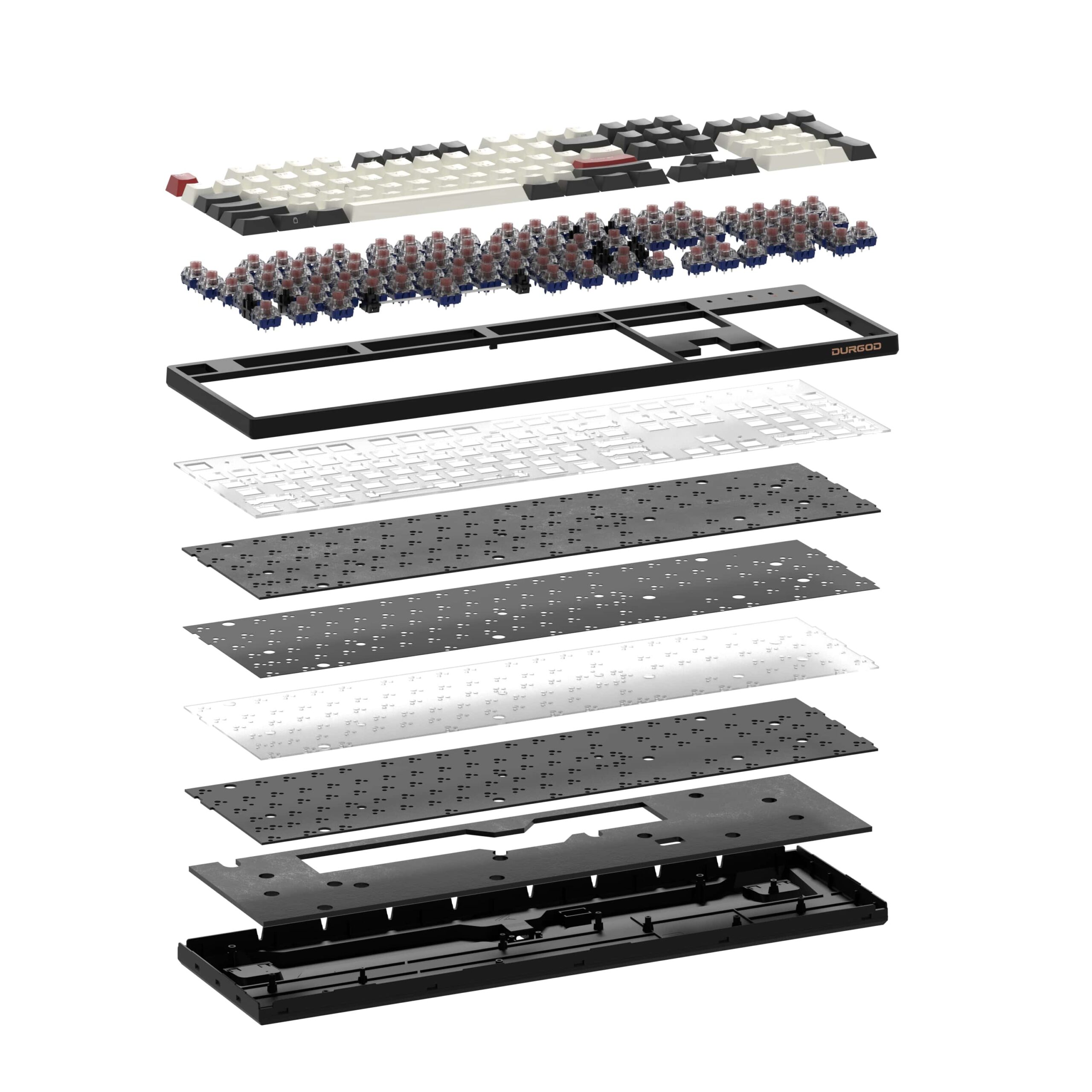

Various components of a mechanical keyboard collaborate to transform key presses into electrical impulses, transmitting them to a computer. Every component plays an essential role and has a considerable influence on the keyboard’s performance, usability, and visual appeal. This guide provides an in-depth look at each part of a keyboard, detailing their functions, popular choices, and how they impact the typing experience for individuals such as writers, gamers, programmers, and business experts.

Everything about a Mechanical Keyboard: At a Glance

This table lists parts of a mechanical keyboard and their functions. Scroll down for more detailed explanations.

Component |

Function Description |

Keycaps |

The individual buttons on the keyboard, are usually made from materials like ABS or PBT. They provide the surface for typing and can be customized for aesthetics and feel. |

Switches |

Mechanical components under each keycap that register keystrokes. They come in various types like tactile, linear, and clicky, each offering a different typing experience. |

Case |

The outer shell houses all keyboard components. It impacts the keyboard’s durability, acoustics, and overall aesthetics. |

Gaskets |

Used in gasket-mounted keyboards, these are typically rubber or silicone strips placed between the plate and the case. They absorb shock, reduce typing noise, and enhance the typing feel. |

Plate |

A rigid framework that sits between the switches and the PCB. It provides stability to the switches and affects the keyboard’s overall feel and sound. |

PCB (PrintedCircuit Board) |

The electronic circuit board that registers the key presses and sends the signal to the computer. It’s the brain of the keyboard. |

Stabilizers |

Used under larger keys (like spacebar, enter, and shift), they stabilize the keycap motion and prevent wobbling during presses. |

Power Cable |

Connects the keyboard to the computer or power source it can be detachable (USB-C or micro-USB) for convenience and portability. |

The below charts show some optional elements that might not be on every mechanical keyboard including:

Component |

Function Description |

2.4G Dongle |

A wireless receiver allows the keyboard to connect to a computer or device without cables, offering convenience and a cleaner desk setup. |

Keyboard Feet |

Adjustable stands at the bottom of the keyboard to change its angle for ergonomic typing comfort. |

Volume Knob |

A physical control for adjusting the system volume directly from the keyboard, enhancing user convenience. |

Media Keys |

Dedicated keys for controlling media playback (play, pause, skip, etc.)allowing easy and quick media control without interrupting workflow. |

LED Indicator Lights |

Lights that show the status of various keyboard functions like Caps Lock. Num Lock, or wireless connectivity. |

O-Rings |

Small rings placed on the switch stems under the keycaps to dampen the sound of the key press and slightly alter the key travel for a softer landing. |

Sleep Button |

A dedicated button to quickly put the computer into sleep mode, aiding in power saving and convenience. |

USB Passthrough |

An additional USB port on the keyboard itself, allows you to connect other devices (like a mouse or a flash drive) directly to it for easier access. |

These are some common materials used for sound insulation or tactile feeling improvement inside a mechanical keyboard.

Type ofFoam/Pad |

Definition and Function |

EVA Foam |

Ethylene-Vinyl Acetate foam, lightweight and rubber-like, is used for reducing sound echo within the keyboard and providing a softer bottoming out of keys. |

Neoprene Foam |

A synthetic rubber foam known for flexibility and durability, used for sound dampening and reducing vibrations. |

Poron Foam |

Microcellular urethane foam offering high durability and excellent compression set resistance, used for effective sound-absorption and cushioning properties. |

Silicone Foam |

Made from silicone, known for high heat resistance and durability, used for sound dampening with a different feel compared to other foams. |

Sorbothane Foam |

A viscoelastic material, known for exceptional vibration-damping and sound absorption, often considered one of the best for these purposes in keyboards. |

IXPE Switch Pad |

Cross-linked polyethylene foam, used underneath the switch for reducing noise and altering the typing feel. lt’s thin and has a relatively firm feel. |

PET Pad |

Polyethylene terephthalate pad, used for sound insulation and to reduce the reverberation inside the keyboard case. lt’s lightweight, durable, and often used in thin layers. |

Everything about a Mechanical Keyboard: A Closer Look

The mechanical keyboard is comprised of several parts, each varying greatly in quality and design across different brands and production methods. It’s crucial to familiarize oneself with these various components and their respective options when considering assembling a custom keyboard or purchasing a pre-assembled one.

Keycaps | Top Appearance of the Mechanical Keyboard

Basic Materials of Keycaps

Keycaps are an essential component of a mechanical keyboard, positioned directly above the mechanical switches. They are the interface that users interact with, pressing them to activate keystrokes. These keycaps, along with the switches, are situated above the top plate. The top plate features holes allowing the switches to connect to both the plate and the PCB beneath. Keycaps can be crafted from various materials, including common plastics like Polybutylene Terephthalate (PBT) and Acrylonitrile Butadiene Styrene (ABS), and more exotic materials like resin, wood, and even metals such as aluminum, stainless steel, or gold.

The Differences between ABS and PBT

PBT keycaps are favored for their robustness and durability. They resist wear and fading, offering a matte, textured feel. These are typically pricier than ABS keycaps, which are known for their flexibility, impact resistance, and vibrant, sharply defined legends. Due to the significant cost difference, ABS keycaps are more prevalent in the market, often found on mass-produced keyboards due to their lower cost.

Regarding manufacturing, keycaps can be classified as:

- Single Shot Keycaps: Constructed from a single layer of plastic.

- Double Shot Keycaps: Comprise two layers of plastic fused. The primary layer forms the main body, while the second layer is injected to create the stem and legend.

Dye-sublimation Keycaps

Additionally, some keycaps undergo dye-sublimation, a process where legends are digitally printed onto the keycaps. Although dye-sublimated keycaps can fade over time, laser-etched and double-shot keycaps do not. Laser-etched keycaps have legends cut into them, preventing fading, whereas double-shot keycaps have legends in a contrasting plastic color, making them durable and resistant to wear. Double shot keycaps are often of higher quality due to the additional material, enhancing their strength and weight.

Keycaps are available in various profiles, which can be categorized by:

- Height: High, medium, or low.

- Shape: Angled or concave.

- Row Shape: Sculpted or uniform.

Among the most popular keycap profiles in the market are Cherry, SA (Spherical All), and OEM (Original Equipment Manufacturer).

- Keycap Profiles: These are largely a matter of personal preference but can influence typing performance. For instance, SA profile keycaps are taller and not optimized for speed, whereas Cherry profile keycaps are flavored among Esports gamers and writers for their optimal balance of comfort, accuracy, and speed.

Mechanical Switches | Soul of the Mechanical Keyboard

What is the mechanical switch?

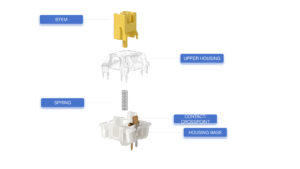

Keyboard switches are a critical component of a keyboard, primarily defining its sound and typing feel, which is also influenced by the keycaps. These switches are essential for transmitting keystrokes to the PCB (Printed Circuit Board) via the crosspoint or contact. Various characteristics define a keyboard switch, including the force required for pressing or releasing the key, its feel (tactile or linear), the sound it produces during typing, the key travel distance, and whether they are unlit, backlit, or RGB switches. Switches are available in different styles, but generally consist of:

- Upper Housing: The top part of the switch where the keycap is mounted.

- Stem: Moves down upon pressing the keycap, activating the contact.

- Contact or Crosspoint: Completes the circuit on the PCB, sending the signal to the computer.

- Spring: Provides resistance and resets the keycap to its original position.

- Housing Base: Secures the switch to the PCB or the keyboard plate.

- LED Pipe: In backlit keyboards, a single color LED light is inserted into the switch.

There are also scissors and butterfly switches, typically found in low-profile keyboards. They use two interlocking arms supported by a spring. Pressing the key collapses these arms, activating the contact on the PCB.

Cherry Switch

Cherry MX is known for its Ultra-Low Profile Butterfly Style Mechanical Switch.

Keyboard switches are categorized into three main actuation types, each offering a distinct typing experience:

- Clicky: Provides tactile feedback with a noticeable click sound.

- Tactile: Offers tactile feedback with a softer click.

- Linear: Delivers a smooth, quieter keystroke, which can be silent.

Other differentiating factors of switches include

- Resistance: The force needed to depress each key.

- Pre-travel Distance: The distance the key travels before registering the keystroke.

- Total Travel Distance: The full distance the key travels until it bottoms out.

- Actuation Rating: The switch’s lifespan in keystrokes.

- Mount: Some switches are designed to mount to the keyboard plate, others directly on the PCB.

It’s important to note that not all keyboards use mechanical switches. Some have single-sheet membranes with raised, printed “keys” that activate the circuit board when pressed, commonly found in low-end or economical models like those on laptops. These keyboards, including those with rubber dome keys, generally lack tactile feedback.

The market is filled with numerous switch brands, including prominent ones like Cherry MX, Gateron, Kailh, Drop, Topre, and Romer-G. Each brand offers various tactile and linear switch options. While exploring different switches before purchasing a keyboard is advisable, Cherry MX Brown switches have been a longstanding popular choice. They feature a quiet click, and tactile feedback, and are rated for over 100 million actuations.

Keyboard Case

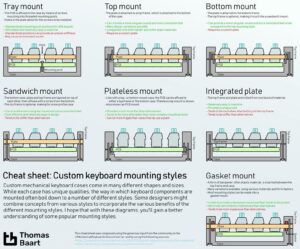

A keyboard typically consists of two main case components: the top case and the bottom case, with the latter also known as the bottom housing. This part encases the keyboard’s lower section, while the top case covers the upper portion. However, not every keyboard design includes a top case, as this varies based on the design and the chosen mounting style. The material used for keyboard cases often includes ABS plastic, but options extend to aluminum, brass, carbon fiber, and even wood for a diverse range of builds and aesthetics. The construction of keyboard cases is characterized by various types of mounting styles:

Gasket Mount: Utilizes gaskets positioned between the plate and the top and bottom cases for sound absorption and dust prevention.

Tray Mount: Designed with posts in the case for securing the circuit board with screws.

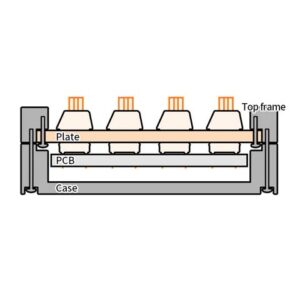

Top-Mount: In this style, the plate is fixed to the upper frame of the case.

Bottom Mount: The plate is connected to the top section of the keyboard’s case.

Plateless Mount: This setup accommodates a keyboard without a plate, directly connecting switches to the PCB.

Sandwich Mount: Features a design where the plate is firmly held between the top and bottom parts of the case.

Integrated Mount: The top case also serves as the plate in this configuration.

Keyboard cases are engineered to encase the keyboard’s electronic components and other elements like the top plate and PCB. These cases are tailored to fit specific keyboard sizes and layouts, ranging from full-sized models to tenkeyless versions that lack a numeric keypad, and 65% keyboards that exclude both the numeric keypad and function keys.

Gaskets

Definition of Gasket Structure in Keyboards:

In mechanical keyboards, a gasket structure refers to a design where gaskets – typically made of soft, compressible materials like rubber or foam – are placed between the keyboard’s plate and its top and bottom cases. This setup acts as a physical buffer, dampening the sound produced during typing and enhancing the overall feel. It also provides a slight flex to the typing surface, offering a more comfortable and less rigid typing experience. Additionally, these gaskets help keep water, liquids, dust, and debris out of the internal components.

Persuading Application Examples of Gasket Structure:

Enhanced Typing Comfort and Reduced Fatigue

The gasket structure’s ability to provide a softer, more cushioned typing experience makes it ideal for individuals who type for extended periods. This can include professionals like writers, programmers, and data entry specialists. The reduced impact on fingertips can significantly diminish typing fatigue, improving productivity and comfort.

Sound Dampening for Noise-Sensitive Environments

The sound-dampening characteristic of the gasket structure is perfect for environments where noise minimization is crucial, such as in shared office spaces, libraries, or home offices in close quarters with living areas. The quieter typing experience allows for less distraction to oneself and others, fostering a more focused and peaceful working environment.

Customization for Enthusiasts and Gamers

Keyboard enthusiasts and gamers who prioritize a personalized typing experience can greatly benefit from the gasket structure. The flex and feel of the keyboard can be fine-tuned by choosing different types of gaskets, providing a unique typing experience that can be tailored to individual preferences, enhancing both gaming and general use.

Durability in High-Use Scenarios

The gasket structure adds an extra layer of protection for the internal components of the keyboard, making it a durable choice for high-use scenarios. In settings like computer labs, customer service centers, or gaming cafes where keyboards are subject to constant use, the added durability can extend the lifespan of the device.

Aesthetic Appeal for the Modern Workspace

For users who value the aesthetic aspect of their workspace, keyboards with a gasket structure offer a sleek and modern design. This can be particularly appealing in contemporary office settings or in-home setups where the look and feel of the equipment contribute to the overall decor and ambiance.

In conclusion, the gasket structure in mechanical keyboards presents a compelling choice for a wide range of users, offering benefits in comfort, sound management, customization, durability, and aesthetics.

Keyboard Stabilizers

Stabilizers, commonly referred to as stabs, play a crucial role in ensuring larger keys like the enter, shift, backspace, caps lock, and spacebar operate smoothly without any wobble, thereby guaranteeing consistent key presses on the usage of mechanical keyboard. They function by extending beneath each keycap, balancing the switch located at the keycap’s center to prevent it from tilting, and ensuring it activates reliably regardless of where the key is pressed.

Without stabilizers, pressing one side of a spacebar could cause it to lean to that side and possibly fail to trigger the switch. Stabilizers ensure that the entire key depresses uniformly, activating the switch effectively. They are also instrumental in minimizing key wobbling and rattling. The two prevalent types of stabilizers are Costar stabilizers, which feature a bar connecting to stabilizer inserts inside the keycap, and Cherry stabilizers, resembling the stem of a Cherry MX switch.

Keyboard stabilizers come in three varieties:

Plate-Mounted: Attach onto the plate.

Screw-In: Fastened directly to the PCB.

Snap-In: Secure directly onto the PCB.

Screw-in stabilizers are often favored for their robust stabilization. Keyboard enthusiasts who build custom keyboards sometimes perform modifications, such as the ‘bandaid mod’, for enhanced support and reduced rattle. This involves trimming two tabs from the stabilizer’s bottom and placing a small bandaid piece on the PCB before stabilizer installation.

Despite its outward simplicity, a keyboard comprises numerous components working in tandem to convert keystrokes into electronic signals for the computer. Each part is vital, with its quality significantly influencing the keyboard’s performance. This is why serious gamers, writers, programmers, and professionals place high importance on keyboards, often opting for mechanical models with top-quality components. Such keyboards not only improve typing speed, accuracy, and comfort but also enhance the overall enjoyment and emotional connection to the keyboarding experience.

Plate

The top plate serves to position and secure the switches, ensuring they maintain firm contact with the PCB. Generally, the switches are fastened into the plate and subsequently soldered onto the PCB. The presence of plates aids in stabilizing the keyboard, enhancing the consistency and precision of each key press. Additionally, they act as a shield for the circuit board, guarding against potential damage and preventing debris from entering through the keys. However, not all keyboards come with plates, which can lead to increased key wobble in the mechanical keyboard. Common materials for plates include plastic and aluminum, though options such as brass, steel, and carbon fiber are also available, offering varied characteristics.

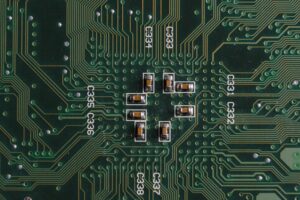

Printed Circuit Board (PCB)

At the core of the keyboard lies the PCB, or Printed Circuit Board, which functions as its central processing unit. It houses essential components like circuitry, resistors, and diodes that transform the physical action of key presses into electronic signals, which are then communicated to a computer. Constructed mainly from glass fiber with copper lines, some PCBs are also equipped with LEDs for RGB backlighting. This backlighting illuminates through transparent RGB switches and corresponding shine-through keycaps. Additionally, PCBs may feature extra elements such as a USB port for charging or data transfer and a volume control mechanism like a wheel or knob. Wireless PCBs often include a dongle port for seamless wireless transmission of keystrokes.

Switches on these PCBs are typically soldered into place. This is the case even with plate-mounted switches, which, while attached to the plates for extra support, are still soldered to the PCB. The plates themselves add further stability to the structure. However, some PCBs offer a hot-swappable feature, allowing for the easy exchange of switches without the need for soldering. While hot-swappable PCBs provide convenience and flexibility in customization, they may lack the stability of their soldered counterparts.

Check out the versatile and stunningly charming mechanical keyboard at DURGOD.